Our company manufactures and supplies three types of HCL-gas generation plants. These are the processes used in the chemical processing industry today. Generators from HCL Gas are designed and manufactured in accordance with current international standards and codes, ensuring product durability, quality, smooth and trouble-free operation.

HCL Gas Generator: Our HCL Gas generator is a compact unit that is installed inside the chemical plant and serves as a backup source for gas supply during emergencies. We are one of India’s leading manufacturers and suppliers of HCL Gas generators. Our products have been extensively used in dry hcl gas generator various industries including petrochemical, pharmaceutical, food & beverage, fertilizer, power and cement. We have vast experience in manufacturing these products with the latest technology and materials. These products are widely demanded in the market for their cost-effectiveness and reliability. We can customize our products according to your specific requirements.

The Generator System of Dry HCL Gas

- Azeotropic Boiling Route

This HCL generation plant is designed to operate continuously under a monitored feed rate of 30% HCL solution. Heat energy is provided to the re-boiler by steam in a thermo-symphony of boiling 30% HCL Solution in an azeotropic distillation column still. During re-boiling, the vapors from the boiler strips the available gas from the feed. The bottom product is a 20% HCL solution that is cooled, stored, treated, and disposed of.

This process has the following salient features:

- Low capital cost

- Simple process

- Compact Design

- Low operating cost

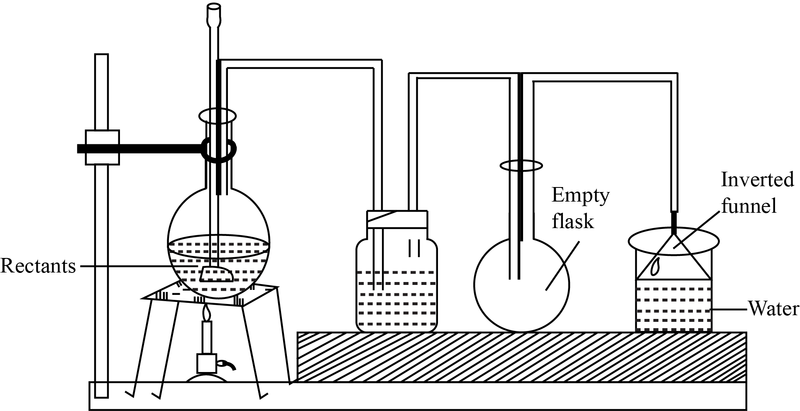

- Sulphuric Acid Route Dry HCL Gas Generator Systems

The HCL Generator Plant uses concentrated sulfuric acid to dehydrate 30% HCL solution and produce dry HCL gas. SA is fed as a co-current from the packed column to 30% HCL sol. from the middle of the column. When the two acids come into contact with the bottom of the column, HCL gas is generated. This plant’s bottom product is spent F A solution (70%) with a small amount of HCL. The final step in this process involves cooling and storing the waste for final disposal.

The HCL Generator Plant operates at a high temperature and produces a large amount of heat. In addition to the heat, the HCL Generator Plant requires large electricity. This is one of the most energy-intensive operations on the site. HCL Generator Plant Process The HCL Generator Plant is a steam-driven, multi-effect evaporator system. Steam is used as a medium to transfer heat. This heat is used to drive the HCL Generator Plant process. The HCL Generator Plant uses a packed column to remove 30% HCL from the solution. This process produces dry HCL gas.The acid is separated from the solids (waste) and sent to a cooling system for further processing. In the HCL Generator Plant, SA is fed as a co-current from the packed column to the 30% HCL sol.

This process has the following salient characteristics:

- Low capital cost

- Simple process

- No drying required

- Compact design

- HCl Gas Generation Unit for Calcium Chloride Route

Azeotropic distillation of 30% HCL solution with calcium chloride solution co-currently produces HCL gas continuously. During the reaction, calcium chloride breaks the azeotrope that forms between HCL and water, resulting in the release of the gaseous form of HCL. As a result of the column, a dilute calcium chloride solution is produced, along with some HCL. In the evaporator, the Calcium Chloride solution is concentrated, and it is recycled to the distillation column. HCL (maximum 1% by weight) makes up 1% of the vapors from the evaporation process. Before discharge to the drain, this vapor is condensed and pH adjusted.

This process has the following salient features:

- No effluent

- Zero discharge

- Lowest operation cost