Swaging machine are used to point, size and form metal wires and rods. They can also reduce the diameter of a rod by forming it into a shaped mandrel.

They can also flange, flare, slot, notches and bond the ends of tubes. These machines are indispensable in the assembly of recreational ropes course cables, sailing rigging components and furniture legs made from tubing.

Types

Swaging machines range from simple, portable, hand-operated devices to large, power-driven swaging presses capable of high-volume production. The most common use of swaging is to attach fittings to pipes or cables (also known as wire ropes); the parts loosely fit together and then a mechanical or hydraulic tool compresses and deforms them, creating a permanent joint. These are sometimes referred to as “swage nipples,” “pipe swages,” or “reducing nipples.” In some cases, legs made from metal tubing in furniture are also swaged to improve strength where they come into contact with the ground or casters.

Another use of swaging is to reduce the diameter of a rod, tube or cable. This is called cold forging and produces a desired tensile strength without introducing heat into the material. This method is commonly used to form the tips of gun barrels and anti-tank rocket ends, or to assemble MS-spec terminals onto galvanized and stainless steel cable. It is also used for forming components such as the reducing nipples on hydraulic control rods, and to create a variety of aerospace tube components.

A third type of swaging is used for assembling items such as recreational ropes course cables, architectural cable railings and marine-industrial terminals. In these applications, a fitting is first placed over the cable and then inserted into the machine to have it swaged into place with a cold-forced hammer action. This produces a fully assembled product, eliminating the need for an intensive and unreliable secondary process.

The swaggering machines available at PROMEC are versatile enough to handle both cold working and hot work operations. This makes them an excellent choice for many industries. The machines can be either manual or powered at the operator’s option and are designed to be free standing, incorporating all necessary systems on a sturdy base. The user controls the machine via a touchscreen HMI and can enter settings into recipes for specific swaging tasks. The user-friendly interface makes it easy to calibrate pressure and gauges as well as to change settings.

Advantages

Using a swaggering machine makes it easy to fabricate metal rods, bars or wires into new, custom-shaped parts. It also allows a manufacturer to produce different shapes and calibers without having to invest in expensive, customized molds. This is especially useful for ammunition manufacturers who may need to experiment with various bullet styles such as jackets, partitions, shot-filled cups and bonded cores.

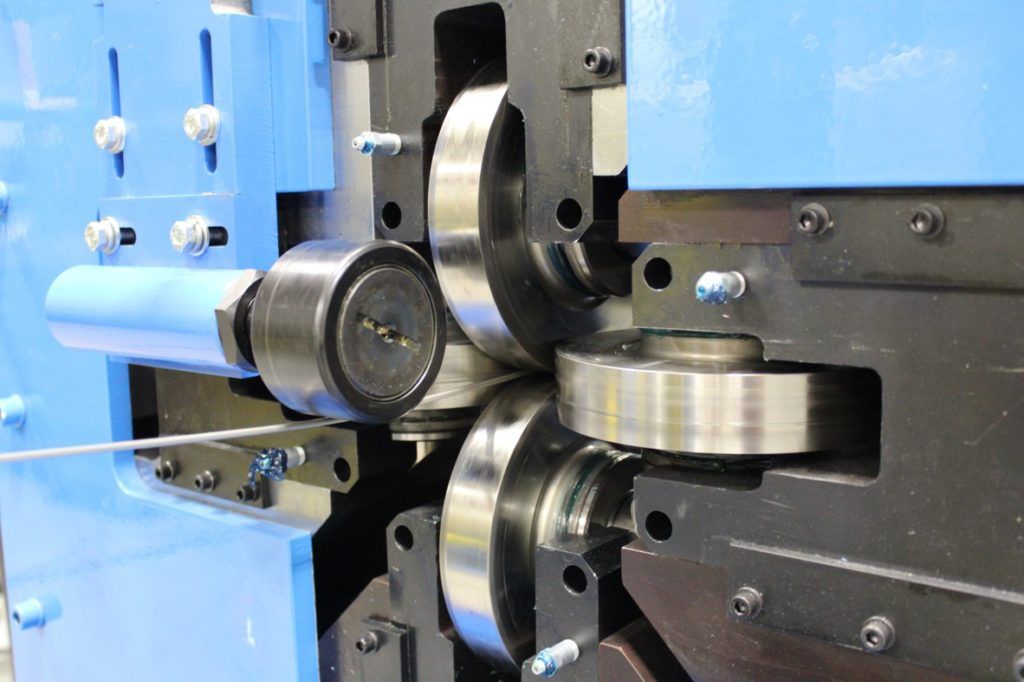

A swaggering machine uses two or four split dies that separate and close up to 2,000 times per minute, creating a swaged section in the metal workpiece. The swaged section is circular in shape and the machine can be used for pointing, sizing and forming metal wires, rods and tubes. It has a rotating spindle that contains rollers and hammer blocks. The hammer blocks are moved in and out of the dies by the rotation of the spindle, producing a centrifugal force that drives the die halves apart each time the hammer strikes them.

Swaging machines can be set to perform both hot and cold swaging operations. The former utilizes a higher temperature to allow the forming of hard metals such as molybdenum and tungsten, which have low ductility at room temperatures. The latter involves less heat, and is used for softer materials like copper and steel bands.

There are several advantages of swaging machines, including the fact that they provide more control over wall thickness than other forming techniques. This means that a metal workpiece can be formed to a specific diameter, without any excess material being left over from the original part.

A swaging machine is also easy to maintain. Its design makes it simple to change the pressure settings with a calibration gauge. Additionally, most swagers can be equipped with a touchscreen HMI (human-machine interface) that allows the user to enter settings in “recipes” that are automatically executed at the touch of a button.

Unlike other methods of forming, swaging doesn’t require the use of punches or cutters, which could damage the original metal workpiece. This saves on labor costs and reduces the need to keep a large inventory of components on hand for each swaging job.